- News

- LEAN journey in the BIM Excellence department

BIM goes LEAN – a progress report

In the BIM Excellence department, the LEAN journey began more than a year ago and the CIP (continuous improvement process) is now our constant companion. When faced with the challenges of the pandemic, we expanded our already extensively digitalised processes to include a digital project board for our KAT GU2 project. This project has been supported by both BIM management and modelling.

Advantages of LEAN as a way of working

With the help of the LEAN approach, we have been able to improve our team’s internal cooperation and make it more efficient, while making it easy to view the time and content-related connections between the individual activities and create the greatest possible transparency regarding deadlines and responsibilities for all those involved. Furthermore, delays and their consequences could be recognised easily and in a timely manner.

The digital project board made it possible to hold weekly meetings with all participants as if in a BIG room, the “command centre” of LEAN, but with the added benefit of spatial independence. This benefit is especially important in a cross-team project team with around 10 BIM managers and modellers actively working on the project at the same time.

The advantages of the LEAN approach were visible right from the project’s start phase: it was easy to precisely define and present processes, assign people and allocate resources.

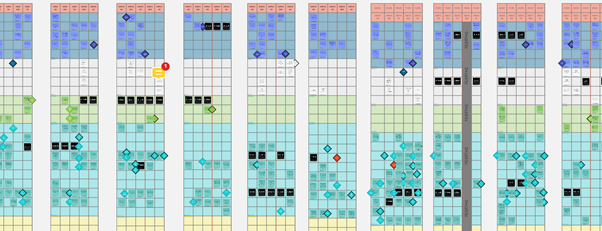

During the planning of the 4-week preview, it was possible to take topics that were jointly processed and interdependent and discuss and plan them as precisely as possible. The coloured background allows things to be structured into different project sub-areas. Absences can also be visualised easily. The targets already laid out are reviewed in the weekly meeting and divided into “done” and “not done”. After this, the next 4 weeks are planned.

Looking at the weeks ahead with the digital project board

Any targets that could not be met are categorised according to the reason for delay and displayed separately under the respective week. In this way, the number of targets met, the so-called NTM value, can be quickly determined and problems can be addressed. For example, if 28 of 35 planned goals were completed, this corresponds to an NTM of 80%. Milestones were not taken into account in the calculation, as they do not require any activity.

In the case of a long project duration, the digital project board also ensures that the development of activities is always traceable. It can be used as a central place for the assignment of tasks and responsibilities and as a digital and transparent to do list. It also provides an overview of planned milestones and any delays that jeopardise milestone achievement.

Key Performance Indicator “NTM” (AEZ) value in the digital project board

For us, the use of the digital project board has not only massively increased transparency and efficiency in the processing of the KAT GU2 project but, surprisingly, has also improved cooperation once again.